Table of Contents

The track chains belong to the undercarriage of various types of heavy machinery, their main function is to connect the forward movement that is produced by the pedals to wheels with driving characteristics in order to cause a continuous forward motion, used in heavy tracked machinery such as excavators and bulldozers

Heavy tracked machinery has a mechanism that prevents the drive wheels from resting directly on the ground, for which they are linked and mesh with sliding bearings that cause the links to articulate with each other to form the chains. In the outer zone of the link a shoe is connected by screws, with which the machine is going to support itself and have a grip with the ground. Generally, the shoes have claws to be able to have an optimal grip with the ground, causing all the weight to rest on the chains, this type of machinery is the most recommended to be able to operate on all types of terrain.

With this mechanism, when there is a rotation of the driving wheels, thanks to the union in the chains, it produces the movement of the machine. The teeth of the driving wheels collect the links that return to the ground on the guide wheels that fulfill the function of guiding the chains so that they return to the ground, continuously generating a forward movement.

TRACK CHAIN STRUCTURE

Unlike excavators, bulldozers require a higher tractive effort, which is why their links are consequently subjected to much greater stress than those of other types of equipment.

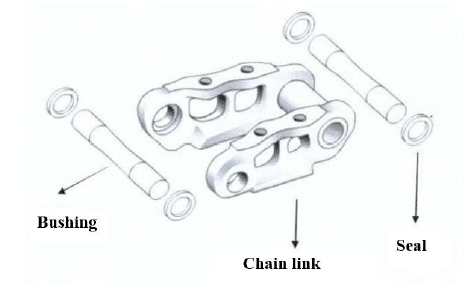

The crawler chains are made up of:

- Links

- Pins

- Bushings

- Seals

- Clamping bolts

- Shoes

LINK

The links generally have an unusual shape, the most important area of the link is the one that will be in contact with the ground, the rolling surface, because it is required to have properties that prevent very fast wear.

Due to the nature of the machinery operation, the link is subjected to roughing and stress when in contact with the ground. On the other hand, it must also withstand high loads from the rollers as the machine moves forward and backward during its operation.

To extend the service life of the links, they are manufactured in materials with high strength in the rolling surface area to meet the most critical requirements. The link assembly, bushing and pin are inserted into the respective opposite sides and ends, ensuring that the pin and bushing do not escape from the link, a press fit is employed. The contact area of the link with the ground has a greater dimension because it is subjected to pressure, achieving a tighter fit. The surface that is subjected to greater stress to improve its hardness property undergoes a heat quenching treatment to ensure that the wear that occurs is not so uneven.

There are two types of link mounts:

– Master link type

The link is divided into sections and connected using bolts, it is recommended due to its ease of mounting for the track shoe.

– Master pin type

Assembly requires removal of the pin to replace it, the master pin is beveled and the master bushing is smaller than the regulating bushing, so that it can be easily removed from its usual position between the links.

BUSHING

The bushing needs to have a high wear resistance, as well as a relevant characteristic it must have tolerance and resistance to fatigue to give the bushing to resist the impacts of the sprocket. The interior and exterior surface due to its operation are subjected to friction and wear, for which a heat treatment is carried out where the piece is tempered to increase its durability.

Usually the external surface of the bushing wears out faster than the internal surface, this is due to the fact that it is in contact with the surface of the sprocket which causes hammering in operation, in addition to that the particulate material of the earth can generate a much greater wear. Additional wear occurs between the pin and the inner surface of the bushing.

PIN

The pin is required to have the ability to withstand the constant tensile stresses of the links and to have a high strength to prevent wear. It is a very important piece because it is responsible for the union of the links. In addition, due to the equipment’s own weight, a high bending force is produced, which is why the pin is designed with high fatigue resistance. There are 2 kinds of pins, the regular pin and the one used for replacement known as the master pin, the regular pin has a larger diameter than the master pin.

SEAL

The life time of the oil lubricated track depends on the type of seal, because if the seal breaks or fails, the oil is released and allows sand to enter the bushing accelerating the wear process of both the bushing and the pin . The sealing stress begins to decrease as the seal wears, causing the inside of the bushing and pin to wear out more rapidly because of internal oil leaks and ingress of sand particles.

LUBRICATION BETWEEN HUB AND PIN

Lubrication by oil seal

The oil-sealed track link seal is comprised of a sealing ring that prevents sand ingress and an oil-lubricating and load-bearing inner ring that generates a compressive force against the seal. The load ring is designed to maintain resilient sealing ability as the link is compressed and embedded.

Lubrication by means of grease sealing

As the sealing ring in the grease seal type is flattened it takes on a similar function as the load ring for the oil sealed type.

TRACK SHOE

A common analogy of the machine shoe is the sole of a common shoe because it fulfills basically the same function, for each type of terrain it is necessary to choose a shoe with a suitable sole, for example, to climb it is not appropriate to use a shoe with smooth sole. The effect is the same in the machinery if the correct track shoe is not chosen the machine will not be able to gain traction optimally.

For example, if in the event that a machine is operating in a terrain with sandy characteristics, it is very likely that the machine will slip if it does not have the appropriate shoes, causing the entire undercarriage assembly to dramatically decrease its useful life. For that reason, the correct selection of track shoes is extremely important for optimal operation and to avoid having to invest more money in future repairs.

STRUCTURE OF THE TRACK SHOE

The track shoe is attached to the links usually using 4 bolts and 4 nuts. There is a wide variety of shoes with various widths and grouser shapes. The track shoe is made up of a plate which supports the full weight of the machine, and a claw that has the objective of exerting traction on the surface of the ground. During operation, the track shoe must overcome stresses such as that caused by the bending force, a frictional force that generates wear and tear. Therefore, track shoes are designed to withstand high loads and with resistance to friction wear. In the design stage, studies and simulations are carried out so that in operation it is avoided that rocks and sand are trapped between the footings.

RECOMMENDATION FOR MAINTENANCE OF THE TRACK CHAIN

Maintenance requires a relatively long time, so it is recommended to carry out a prior maintenance schedule to avoid interrupting the usual operation of the equipment, which produces a significant economic loss, in addition to that it is necessary to carry out periodic inspections that will prevent costly repairs to the undercarriage elements from being required.

Undercarriage represents a large machine cost, it is virtually impossible to avoid wear despite excellent design and quality, however understanding the causes of wear in combination with inspection methods and good maintenance practices will achieve increase the life of the undercarriage.

The points where inspection is usually most important are:

- Link pitch: The relationship between wear on the inside diameter of the bushing and the outside of the pin is measured.

- Height of link bearing surface: The degree of wear on the link bearing surface is measured.

- Outside diameter of the bushing : measures the state of wear.

A visual inspection should be done to:

- Determine if there are cracks in the links

- Check that the shoe bolts are properly tightened

- Inspect if there is any oil leakage, in the type of links sealed with oil, it can be verified by the appearance, or by the temperature between the pin and the bushing.

In scheduled track link maintenance, the sprocket teeth must be replaced to ensure the longest undercarriage life. Because if only the track links are changed, the existing wear on the bushings will be greater at that time, for which in economic terms it is recommended to modify both at the same time.

ADJUSTING THE TRACK CLEARANCE IN THE EXCAVATOR CHAINS

When inspecting track chain machines, it is common to notice that the chains are excessively tight, which generates greater wear on the bushings, sprockets, and sprockets, causing the useful life of the assembly to be reduced. It is common that on occasions the rollers, shoes and links are in an optimal state for operation, but on the other hand the bushings and sprockets are at the limit of wear.

There are 2 possible scenarios, that the track chain tension is too low or too tight, in the case of very low tension it causes the bushings to be mounted on the sprocket in operation, there is also the possibility that the chain jumps over the edge of the guide wheel.

Each piece of equipment has a specified tolerance value, so the chain slack should be governed by the manufacturer’s recommendations before making the adjustment.

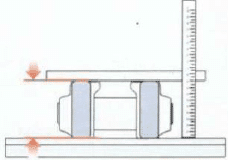

To make the adjustment it is necessary to lift the machine with the arm until the chain of the raised part is hanging above the ground. Turn on the equipment to get the track into operation making at least one full turn. It is required to measure the distance between the surface of the chain and the surface of the lower roller in the center of the track. If the clearance is outside the recommended tolerance range, the tightening is generally carried out with a grease fitting. If the chain is too tight, too little slack, adjustment is also required. On almost all excavators there is a relief bolt mounted where the grease is required.

SECURITY TIP

To be able to work on the tracks, check that the equipment cannot be moved, before making any changes to the equipment, the operation and maintenance manual of the machine should be read to obtain the correct information on making the adjustment. As a basic maintenance rule, it is required that at least three members of the body must be in contact with the steps or support bars, this requirement is essential because the force applied to the track tensioners is quite high and can present a risk. to the physical integrity of the operator.

TIPS TO IMPROVE THE LIFE OF THE UNDERCARRIAGE

A key advice is to strictly follow the maintenance plan recommended in the previous section, regarding the useful life of the undercarriage parts it is recommended to follow the following instructions to increase the useful life:

- The equipment must work with an appropriate speed

- Check that the tension of the crawler chains is correct

- It is not convenient for the equipment to turn sharply.

- Avoid turning in the same direction

- Perform periodic cleaning to remove sludge that accumulates on undercarriage parts.

- It is recommended to park the machine on flat surfaces.

- Replace immediately if necessary: steals, links busted or very worn and internal packing ring to maintain proper axial.

FREQUENTLY ASKED QUESTIONS (FAQ SECTION)

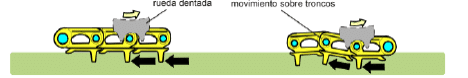

What happens if the shoe assembly is installed in the opposite direction?

There are several consequences such as:

- Track link bushings and sprocket teeth will speed up their wear process

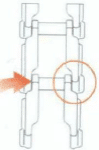

- If the shoe is placed in the opposite direction, the teeth of the sprocket will engage in the link bushing at the bottom of the sprocket, on the other hand, when installed in the proper position, the coupling occurs in the part top of the wheel.

- Due to the position of the shoe, sand and dirt may enter between the bushing and the teeth of the sprocket, causing wear on both.

- Because the track link is screwed to the ground, it produces an unwanted movement that significantly reduces the traction force.

In figure A the track shoe is installed correctly, while in figure B it is evident that the installation was incorrect, so the final movement is not as expected.

Why do bushings wear faster when machine backs up?

When the equipment is in operation and backwards, a tractive force is produced that generates greater wear. The hubs and teeth of the sprocket maintain mutual contact at the top of the sprocket. When the machine backs up, a high tractive force is built into the part, accelerating wear.

What kind of instruments are required to do the inspections on the track chain?

It depends on the type of inspection that is required, some, as already mentioned, require a prior visual inspection. In addition, prior to carrying out any type of inspection, cleaning is necessary to remove the side or sand from the chain.

On the other hand, for each type of inspection a different instrument is required, below are the instruments used in the most common measurements:

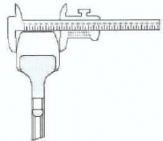

- Measure the wear at the height of the links you need a ruler, a vernier caliper or a depth gauge

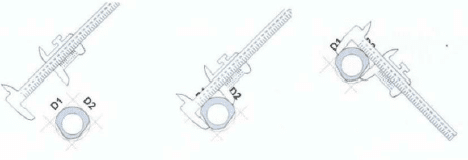

- To measure the wear of the bushing, a vernier caliper is used taking measurements of the external diameters in different positions measuring two diameters, D1 and D2, to record the difference between the values and corroborate the wear.

- Measurement of distance between the links of the chain, measuring gauges are used to measure the distance between the interior and exterior of the element, two points are measured and averaged.

- Measurement of the width of the sprocket, a record of the tooth width is taken on the sprocket and an average is obtained.

- Measure the profile of the teeth of the wheel, to do it you need a previous deep cleaning, you must use gauges to measure the wear of the wheels, readings are taken, a record is required for two different teeth and obtain an average

0 Comments