Table of Contents

The tightness of the excavator’s track is like the size of a person’s shoes, and it must be adjusted to the best condition to move forward. Excavators often cause changes in the tightness of the track chain during the walking operation, and the tightness of the track chain also determines the degree of wear of the chain on its contact accessories.

Therefore, adjusting the tightness of the excavator track is a required course for everyone.

The importance of track tightness

We all know that the “four wheels and one belt” on the lower frame have tensioners, support wheels, sprocket wheels, driving wheels, and track chains. Some excavators always need to replace the supporting wheels and sprocket wheels, and some can be used for a long time, which is closely related to the tightness of the track chain, so the tightness of the track chain should be flexibly adjusted under different working conditions. Is the correct way to use it.

The principle of track adjustment

The first point:

When the excavator is working on hard ground, the track needs to be adjusted slightly tighter, so as to avoid the track from being too long, colliding with the lower frame, and causing wear.

The second point:

When the excavator is working on soft ground, it is best to adjust the track loosely, because this working condition is easy to adhere to the soil on the chain link and crawler, which can reduce the abnormal pressure of the soil on the chain link.

The third point:

When adjusting the tightness of the track, do not adjust it too loosely or too tightly. It must be moderate. If the track is too tight, it will affect the walking speed and walking power, and it will increase the amount of wear between various components. Loose, slack track will cause a lot of wear on the driving wheel and drag sprocket.

Note:

One thing that will be overlooked by many people. When the loose track sags too much, it is very likely to contact the frame and wear the frame. Therefore, an accuracy must be mastered when adjusting, otherwise failures will definitely follow!

Track tension standard

Rotate the excavator to a vertical position and move the single-sided crawler away from the ground. Normally, the longest distance between the lower frame and the chain is about 320mm-340mm.

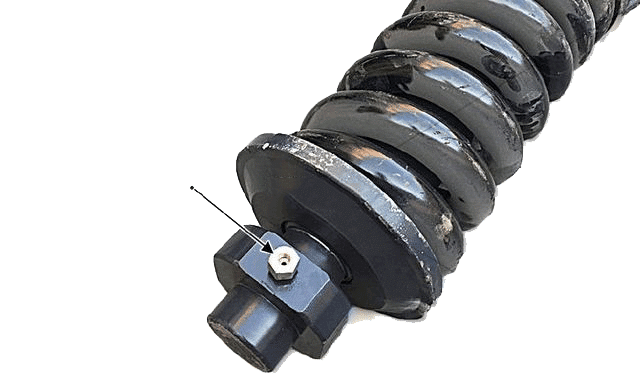

Speaking of the adjustment of the track tightness, the tensioning device must be inseparable. The tensioning device is installed at the front end of the lower frame. The main tensioning cylinder is inside the frame. The tensioning wheel connected in the front is closely matched with the chain. The side of the frame There is a grease filling port for the tightening cylinder.

Maintenance of tightening cylinder

Many people think that as long as the track tightness is appropriate, the tensioning cylinder does not need maintenance. In fact, this is a wrong view. We all know that other oil cylinders on excavators, such as bucket, forearm, and boom cylinders, their cylinder rods will retract into the cylinder barrel to be lubricated and maintained by hydraulic oil when working, while the tightening cylinder rods can usually There is no such big expansion, only a short compressed amount of expansion.

This causes the front end of the cylinder rod to always be exposed to air, dust, and even muddy water. Therefore, if maintenance is not carried out for a long time, the cylinder rod of the tensioning cylinder is easily corroded and damages the surface coating.

In fact, the maintenance and tightening of the cylinder is very simple. We first loosen the grease nipple of the cylinder for 1 to 2 turns, discharge the cylinder barrel grease, and retract the cylinder rod. Then tighten the grease nipple and add new grease to check whether the surface of the cylinder rod is abnormal. If necessary, apply grease on the cylinder rod to complete the maintenance of the tensioning cylinder.

Failure phenomenon of tightening cylinder

The most common failure phenomenon of the tightening oil cylinder is that the new butter cannot be injected and the old butter cannot be released. This situation is mostly caused by the tightness of the cylinder rod surface and the cylinder head oil seal, which makes the cylinder rod unable to move, and the fluidity of the butter in the cylinder barrel is very poor, which plays a role of sealing, so once the tensioning cylinder is on the cylinder head The place is jammed and it is very troublesome to deal with. Only use a jack to push out the cylinder.

In general, first of all, the tension of the excavator’s track cannot be adjusted at will. Only in accordance with the standard can the “four wheels and one belt” be better protected. In addition, you must not neglect the maintenance of the tensioning cylinder. This device directly affects the tightness of the track chain, and it is very easy to jam, so be sure to pay attention to its status in real time!.

0 Comments